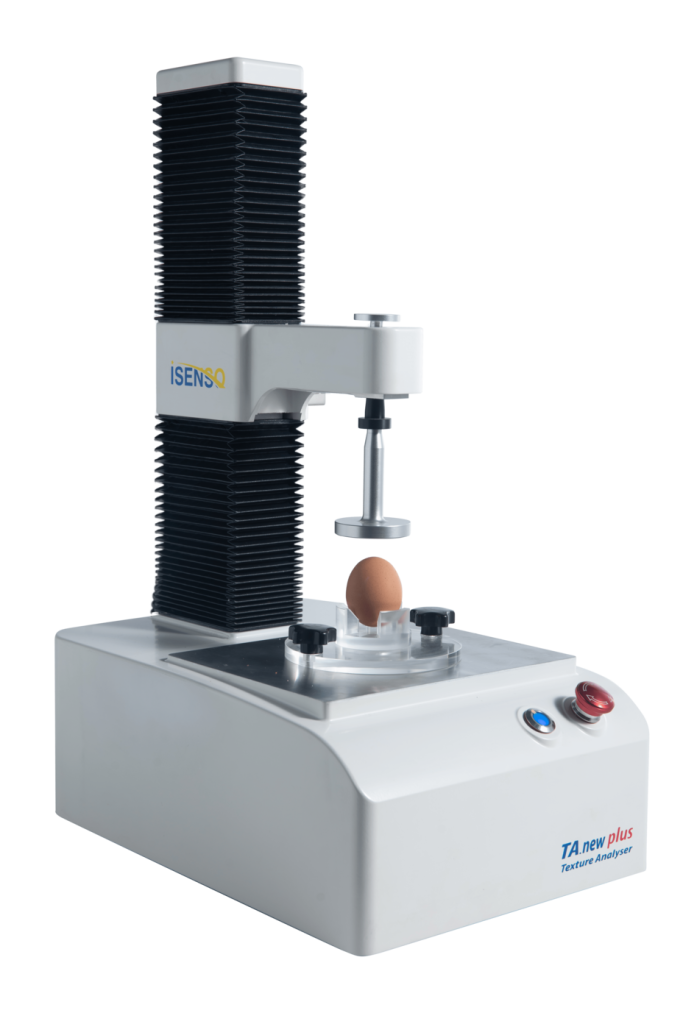

A Texture Analyser is a meticulously engineered instrument designed to accurately measure and quantify the physical and mechanical properties of materials. This sophisticated tool leverages advanced scientific and technological principles. Using methods such as compression, extrusion, shearing, snapping, and bending, the Isenso Group‘s texture analysis software evaluates parameters like gumminess, adhesiveness, chewiness, and elasticity.

Renowned for its versatile applications across various industries, from food production to pharmaceuticals, the Texture Analyser is essential for studying the physical attributes of products and materials.

Whatch video to

see details

Texture Analysers are indispensable in quality control, product development, and research across a wide range of industries. They enable manufacturers and researchers to conduct objective, precise evaluations of material properties, enhancing product quality and manufacturing processes. These insights drive continuous improvement and innovation.

At ISENSO Group, our researchers are dedicated to providing cutting-edge tools and systems for comprehensive material texture and composition analysis. Our commitment to innovation and development ensures that you have the state-of-the-art resources needed for accurate and reliable analysis.

For more information

© Isenso Group. All right reserved.