Polymers Industry & Dental Material

Nowadays, scientific and technological development has reached a spectacular pace. Advances in manufacturing are evident in various aspects of our daily lives, requiring engineers and industry professionals to stay up-to-date with the latest in technology and innovation. Organic chemistry revolutionized human life with the development of polymers, which, due to their numerous applications, have become indispensable in automobile manufacturing, electronic device production, construction, dental prosthesis design, packaging, and more.

UNDERSTANDING POLYMERS

What is a Polymer ?

Polymers are macromolecules composed of repetitive linkages of one or multiple molecular units through covalent bonds. While the terms ‘polymer’ and ‘macromolecule’ are frequently used interchangeably, it’s essential to emphasize that macromolecules do not inherently consist of recurring units. Polymers are broadly categorized into two primary classes: natural and synthetic. Synthetic polymers, especially, hold substantial commercial significance. The molecules that amalgamate to create polymers are called monomers, and the chemical processes responsible for their formation are referred to as polymerization reactions.

POLYMERS INDUSTRY

Uncovering Performance-Impacting Flaws:

The Vital Role of Texture Analysers

In the dynamic realm of material analysis, Texture Analyzers emerge as unsung heroes, diligently uncovering performance-impacting flaws. These sophisticated instruments not only deliver precision but also pave the way for innovation, from the characterization of polymer materials to the accelerated development and tailored textural proficiency of products.

Enhancing Material Analysis: Texture Analyzers deliver precise measurements for critical parameters, including tensile strength, compressibility, hardness, and elasticity, thereby facilitating the comprehensive characterization of polymer materials.

Empowering Research Excellence: Researchers leverage Texture Analyzers to fine-tune polymer formulations by adjusting ingredients and refining processing conditions, ultimately achieving the desired mechanical properties and textures. This fuels the development of innovative materials with specific textures and mechanical attributes, broadening the spectrum of polymer applications.

Streamlined Development: By employing Texture Analyzers to evaluate mechanical properties, manufacturers can expedite the development and production of polymer materials, enabling faster innovation and delivery to market.

Tailored Textural Proficiency: Texture Analyzers empower companies to craft tailored texture profiles, facilitating the creation of unique textures for their polymer materials that align precisely with distinct customer requirements.

DENTAL MATERIAL

Mastering Dental Materials:

HOW TEXTURE ANALYSERS REDEFINE PRECISION AND INNOVATION

In the dynamic realm of dental materials, Texture Analyzers are trailblazers, driving the innovation and precision required for the development of cutting-edge dental solutions. ISENSO Group’s Texture Analyzer revolutionizes the science of polymers in the dental material industry by providing quality control for products under study, optimizing procedures, fostering the development of new materials, and promoting research and study of dental sealants, prosthetics, crowns, and other essential elements for the demanding dental care sector.

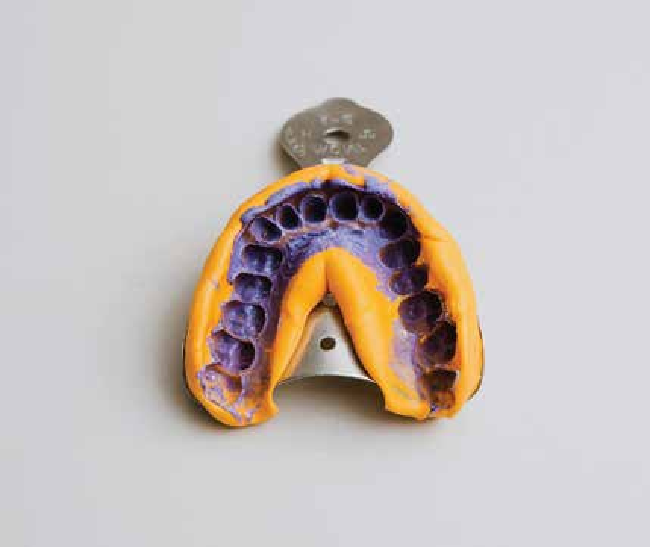

Crafting Perfected Formulations: Texture Analyzers are key in empowering researchers to craft dental materials with bespoke texture and mechanical characteristics. These encompass adhesives, composites, cements, and impression materials, ensuring that each material’s performance and quality exceed industry expectations.

Elevating Quality Control: In the sphere of developing and assuring the quality of restorative dental materials, our Analyzers take center stage. They provide invaluable insights into attributes like strength, hardness, and wear resistance, ensuring that dental products not only meet but exceed the most stringent industry standards.

Accelerating Progress: Texture Analyzers play a crucial role in assessing the texture and softness of dental impression materials. This accelerates the development process, while also delivering cost-effective and repeatable testing procedures, diminishing the need for labor-intensive manual testing and quality control protocols.